WhatsApp)

WhatsApp)

Nov 12, 2019· Minerals also form when minerals are mixed in water. Most water on Earth, like the water in the oceans, contains minerals. The minerals are mixed evenly throughout the water to make a solution. The mineral particles in water are so small that they will not come out when you filter the water.

INTRODUCTION TO MINING MINING''S CONTRIBUTION TO CIVILIZATION Mining may well have been the second of humankind''s earliest endeavors— granted that agriculture was the first. The two industries ranked together as the primary or basic industries of early civilization. Little has changed in the

Jun 22, 2018· The mining process is responsible for much of the energy we use and products we consume. Mining has been a vital part of American economy and the stages of the mining process have had little fluctuation. However, the process of mining for ore is intricate and requires meticulous work procedures to be efficient and effective. This is why we have ...

Commercial Process of Bioleaching: The naturally occurring mineral leaching is very slow. The microbial bioleaching process can be optimized by creating ideal conditions— temperature, pH, and nutrient, O 2 and CO 2 supply etc. A diagrammatic representation of general bioleaching process .

octahedra. The process of replacing one structural cation for another of similar size is referred to as isomorphous substitution. This replacement represents the primary source of both negative and positive charges in clay minerals. For example, the substitution of one Al3+ for a Si4+ in the tetrahedron results in a gain of one negative charge.

Mineral extraction sites, which include strip mines, quarries, and underground mines, contribute to surface water and groundwater pollution, erosion, and sedimentation (see Chapter 14). The mining process involves the excavation of large amounts of waste rock in order to remove the desired mineral ore (Fig. ). The ore is then crushed into ...

Thank you for your interest in the Responsible Minerals Initiative. To gain access to the information you have selected to view, please review the following Terms Conditions, before clicking "I AGREE".

Best Management Practices for Reclaiming Surface Mines in Washington and Oregon by David K. Norman, Peter J. Wampler, Allen H. Throop, E. Frank Schnitzer, and Jaretta M. Roloff WASHINGTON DIVISION OF GEOLOGY AND EARTH RESOURCES Open File Report 962 also released as OREGON DEPARTMENT OF GEOLOGY AND MINERAL INDUSTRIES OpenFile Report O962 ...

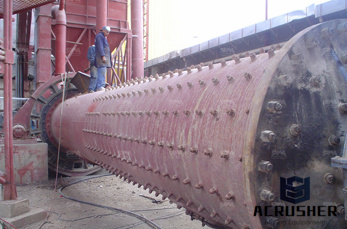

Mineral Processing Plant Design General Procedure for plant design ... The design process Arranging in diagrammatic form the necessary equipment, installations and ... In mining operations, the layout of crushing plants and ancillary equipment and ...

All minerals are stored in your body, but only some vitamins actually stay in your body. Vitamins are broken up into two categories: fat soluble, such as A, D, E or K, and water soluble, including all of the B vitamins and vitamin C. Fatsoluble vitamins stay in your body, whereas watersoluble vitamins are absorbed immediately, with any excess being excreted in urine.

The Mineral Mining and Processing effluent guidelines apply to wastewater discharges from facilities in 21 subcategories covering extraction of a wide variety of minerals. Examples, with their corresponding NAICS codes, are: construction materials (, stone, gypsum, asphalt, sand gravel); NAICS 21231, 212319, 212321, 212399.

Jun 10, 2013· Nomenclature for mineral solid solutions Enxnsr H. Nrcxnr.* c B A. Diagrammatic representation of a complete ternary on New Minerals and solid solution series. A, B, and C represent the three composi tional fields, each of . »More detailed

The Mining Process. The Mining Process. 1. Mining – open pit and underground. To define the ore from the waste rock, samples are taken and assayed. Assay results are used to mark out areas of ore and waste rock, which are mined separately. Some of the harder areas require blasting to loosen the rock prior to excavation by hydraulic diggers.

Interesting Facts about Rocks and Minerals. A rock is a solid substance that occurs naturally due to geological process of solidification, sedimentation and metamorphism. Every rock is made up of various minerals. However, a mineral is an inorganic solid that has one chemical composition. The structure of a rock is not uniform.

Mining, process of extracting useful minerals from the surface of the Earth, including the seas. A mineral, with a few exceptions, is an inorganic substance occurring in nature that has a definite chemical composition and distinctive physical properties or molecular structure. (One organic

The manufacturing process has six general phases: 1) mining and storage of raw materials, 2) preparing raw materials, 3) forming the brick, 4) drying, 5) firing and cooling and 6) dehacking and storing finished products (see Figure 1). Figure 1 . Diagrammatic Representation of Manufacturing Process . Mining and Storage. Surface clays, shales ...

Mining and processing of mineral resources normally have a considerable impact on land, water, air, and biologic impacts result from the increased demand for housing and other services in mining areas. 1. Pollution: Mining operations often pollute the .

The Mining Process. Finding new mineral reserves is critical to the success of our company. Locating, extracting and processing these natural resources is a multiyear process that involves complex scientific, environmental and social planning.

Close observation and perhaps a magnifying glass are all you need for this step in the mineral identification process. 07. of 10. Cleavage and Fracture . How minerals break is a key clue to their identification. Andrew Alden. Cleavage describes the way a mineral breaks. Many minerals break along flat planes or cleavages.

Fluorescent minerals: One of the most spectacular museum exhibits is a dark room filled with fluorescent rocks and minerals that are illuminated with ultraviolet light. They glow with an amazing array of vibrant colors in sharp contrast to the color of the rocks under conditions of normal illumination.

In 2008, competition in the coal mining industry became more intense than ever, leading to a demand for better technology and new mines. History of Mining Technology. In the beginning, miners used primitive tools for digging. Mining shafts were dug out by hand or using stone tools, making the entire process .

In ore beneficiation, flotation is a process in which valuable minerals are separated from worthless material or other valuable minerals by inducing them to gather in and on the surface of a froth layer. Sulfide and nonsulfide minerals as well as native metals are recovered by froth flotation.

Classification of Igneous Rocks As has already been described, igneous rocks are classified into four categories, based on either their chemistry or their mineral composition: felsic, intermediate, mafic, and ultramafic. The diagram in Figure can be used to help classify igneous rocks by their mineral .

This type of mining is particularly damaging to the environment because strategic minerals are often only available in small concentrations, which increases the amount of ore needed to be mined. Environmental hazards are present during every step of the openpit mining process. Hardrock mining exposes rock that has lain unexposed for geological ...

WhatsApp)

WhatsApp)