WhatsApp)

WhatsApp)

(Keywords: maintenance, strategy, industry, management, critical equipment) INTRODUCTION Manufacturing industries and business organizations are set up primarily to meet the thirst or need for a particular commodity. Apart from this primary objective of societal satisfaction, ... These six key functions will form the foundation and backbone of ...

India is the second largest producer of cement in the world. No wonder, India''s cement industry is a vital part of its economy, providing employment to more than a million people, directly or indirectly. Ever since it was deregulated in 1982, the Indian cement industry has attracted huge investments ...

In California, the cement industry employs approximately 1,990 workers and has an annual value of shipments of about 850 million. Table 21 presents economic statistics for the California cement industry, as compared to cement industry totals. Table 21 Cement Industry Economic Statistics California CA share of

AnnexureIII LIST OF MAJOR CONSTRUCTION PLANTS EQUIPMENTS CODE NO. CODE DESCRIPTION EARTH MOVING EQUIPMENT: 0101 Dozer 0102 .

CEMENT INDUSTRY Overview Current Scenario of the Indian Cement Industry! Historical Production and Growth! Indian cement production commenced in 1914, growing slowly over the next 65 years with a production of only 27 million MT of capacity through the period. Severe competition from imported cement combined with various

Key Findings in the Global Cement Study: Cooling Chinese Economy Will Limit Gains Although many lowincome countries will see healthy growth in cement demand, the Chinese market is forecast to decline through 2023.

Cement is thought to be older than humanity itself, having formed naturally 12 million years ago, when burnt limestone reacted with oil shale. Concrete dates back to at least 6500 BCE when the Nabatea of what we know now as Syria and Jordan used a precursor of modernday concrete to build structures that survive to this day.

Global Cement brings you essential news, events, research and market data on the global cement industry. Global Cement covers all aspects of the cement industry: mining and quarrying, refractories, process optimisation, monitoring, alternative fuels, environment and safety, markets, country reviews, cement prices, trading and shipping and a full review of global cement news.

The objective of cement plants equipments is to improve the product quality. The raw material used in cement plants are sand, clay, limestone, shale, and iron ore. Cement plants require areas where infrastructure rehabilitation is necessary. Offer Complete Turnkey Solution, Key Services Offered Complete Project Consultancy

energy efficiency of china''s cement industry ScienceDirect. 305 to 671 units in the same By importing equipment, the cement industry was able to put 16 clinker and the average fuel intensity of the key wetprocess plants was about 205 kgce/tonneclinker.''

From crisp packets to concrete buildings: the European Cement Industry demonstrates how everyday waste fuels cement manufacturing CEMBUREAU''s response to The Guardian''s ''Concrete Week'' Eurelectric and Energyintensive industries call for an ambitious and comprehensive EU Industrial Strategy to enable industry''s contribution to the EU ...

The cement industry can also take advantage of opportunities for industrial symbiosis – including using the waste or byproducts from one process to produce another product of value – to help close the material loop, reduce energy use and reduce emissions in the case of carbon capture and utilisation.

Emerging trends in concrete and cementbased products are completely changing the design and construction worlds. Skip To The Main Content. ... White cement is the key ingredient in decorative concrete. New coloring agents and admixtures help create beautiful structures and landscapes. ... The TiltUp industry is reaching new heights with the ...

Jun 29, 2010· Key Metrics On 25 Industries. ... from insurance to cement manufacturing. The data are drawn from financial statements on nearly 300,000 companies, most .

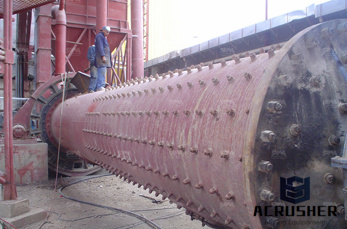

key equipment in cement industry Cement Mill cement grinding optimisation Fote. Cement mill is one of the major cement equipments, and is the key equipment for grinding materials after being broken, so it plays a crucial role in cement production. Get More Info. image . INDUSTRIAL CASE STUDY: THE CEMENT INDUSTRY

and turnover in selected manufacturing cement companies in Cross River State, Nigeria. ... and managerial resilience as key drivers of health and safety performance. The author noted ... safety equipments, with adverse effects on employees and the organizational performance.

key equipment in cement industry supremewheelscoza. Cement mill is one of the major cement equipments, and is the key equipment for grinding materials after being broken, so it plays a crucial role in cement production Get More Info image INDUSTRIAL CASE STUDY: THE CEMENT INDUSTRY

ABB''s Cement FingerPrint is a process optimization and energy consulting service designed to capture, analyze and improve operational performance and energy efficiency of the cement making process. Using ABB''s analytical and process modeling tools, complimented with indepth industry specific

Ashoka''s cement plant unit has continued focused on objectives of product improvement and quality. In our entire turnkey cement plant equipments and machinery, we supply a complete assembly consisting of different machines and equipment, which facilitate the plant to execute efficiently and manufacture a betterquality completed product as per the international quality standards.

construction equipment industry look attractive with a, equipment and is one of the key international market The growth in this industry is expected to be primarily due to investments in infrastructure, investments by the, cement industry has propelled the growth for larger excavators The key players in this sector are Telcon, LT

Welcome to CemNet B2B The cement industry supplier directory Locate a company or product in the cement industry using the search engine, alternatively pick a product/service from the main categories below to find companies specialising in that field.

A showcase of Cement Companies in India, incl. the list of top Cement Manufacturers – along with a short overview of each company, sales turnover, important milestones and other key information – Presented by Govt. Trust, India Brand Equity Foundation (IBEF).

capability of process equipment. The documentation of standard operating practices assures the consistent and correct operation of equipment to maximize performance. The third requirement is Maintenance Practices that maintain the inherent capability of the equipment. Deterioration begins to take place as soon as equipment is commissioned.

Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with silicabearing minerals to form a mixture of calcium a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their capacity usually defines the capacity of the cement plant.

WhatsApp)

WhatsApp)