WhatsApp)

WhatsApp)

Portland slag cement is obtained by mixing Portland cement clinker, gyplum and Ifanulated sla,in suitable proportions and grinding the mixture to get I thorough and intimate mix between the consti tuents. It may also be manufactured by separately grinding Portland cement clinker, gypsum and granulated slag and then mixing them intimately.

Standards (BIS), Confederation of Indian Industry (CII), Corporate Product Quality Management * Responsible for Operation and maintenance of Grinding Aid mixing plant and ensuring availability of the required quantity of the same for daily consumption in Cement manufacturing.

SCBL operates a cement grinding mill; it grinds together all the necessary raw materials in order to produce cement. Find below the general process to produce cement, each factory differs in the ratio of raw materials used in order to produce their product.

Portland cement for blending with fly ash shall conform to IS 269 : 1989. Other Admixtares When Portlandpozzolana cement is obtained by grinding fly ash with Portland cement clinker, no material other than gypsum ( natural or chemical ) or water or both, shall be added.

grindingmill govt norms of cement grinding unit installation in u. govt norms of cement grinding unit installation in u HomeSolutionsgovt norms of cement grinding unit installation in u while a Vertical Roller Mill VRM During the year the Dubai cement.

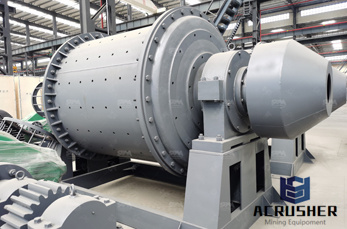

mineral grinding to concrete company dieboldbau Mineral Grinding Unit Norms ediccentralmaltaeu. mineral grinding unit norms mineral grinding unit norms iron ore ball mill a ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral Get Price Online productivity norms for cement grinding unit. More.

Cement Cement Cement testing: Various tests to which cements must conform are laid down in national cement specifications to control the fineness, soundness, setting time, and strength of the cement. These tests are described in turn below. Fineness was long controlled by sieve tests, but more sophisticated methods are now largely used.

Bis Norms Of Cement Grinding Prompt : Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc.

May 28, 2020· 2. Holistic monitoring of your process from incoming raw materials, fuels, grinding efficiency to production and strength of your cement 3. Intelligent and high throughput analytical solutions – for online monitoring or laboratory analysis 4. How to comply to international norms .

Cement is stored in 4 x 7500 T cement concrete silos. A sophisticated bulk cement terminal (which subscribes to all environmental norms) dispatches cement in bulk form to RMC and asbestos plants. The terminal also has a modern Italian make Ventomatic packer to pack cement in 50 kg paper bags to service customers on the island.

The cement plant has the capacity to produce Million Tons per year which is located in Nimbahera, District Chittorgarh, in Rajasthan. In technical collaboration with ThyssenKrupp and Pfeiffer Ltd. of Germany, the world leaders in cement technology, the world leaders in cement technology, the state of the art manufacturing unit was established.

The important amendments included: use of performance improvers for addition during clinker grinding stage, incorporation of requirement of chloride content for the cement used in structures other than prestressed concrete, permitting use of 25 kg, 10 kg, 5 kg, 2 kg and 1 kg bags for packing of cement, and requirements of packing cement for export.

BURNPUR CEMENT LIMITED is one of the most reputed and largest integrated cement companies in eastern India with two units at Asansol, West Bengal and Patratu, Jharkhand. (033) 2262 3167; cs; 7/1 Anandilal Poddar Sarani (Russel Street) 5th floor, Flat No 5B, Kanchana Building, Kolkata 700071

BUREAU OF INDIAN STANDARDS (CENTRAL MARKS DEPARTMENT I) Our Ref: CMDI/2:12:1 29 October 2018 Sub: Guidelines for Grant of Licence (GoL) as per the conformity assessment Scheme – I of Schedule – II of BIS (Conformity Assessment) Regulations, 2018

of cement. The important amendments included: use of performance improvers for addition during clinker grinding stage, incorporation of requirement of chloride content for the cement used in structures other than prestressed concrete, permitting use of 25 kg, 10 kg, 5 kg, 2 kg and 1 kg bags for packing of cement, and requirement of

Bis Norms Of Cement Grinding Liefsliekenl. Clinker Ginding Units Pollution Norms. bis norms of cement grinding cithrah Govt Norms Of Cement Grinding Unit Cement Cement Clinker grinding unit for quart near by kurnool cement in india grinding Tamil Nadu Pollution JSW About Salboni Works The plant is committed to the environment with highly advanced pollution control for clinker

Addeddate 11:24:57 Identifier Identifierark ark:/13960/t0sr0rn23 Ocr ABBYY FineReader Ppi 300 Rights Published under the auspices of the Right to Information Act 2005

Cement Cement Cement testing: Various tests to which cements must conform are laid down in national cement specifications to control the fineness, soundness, setting time, and strength of the cement. These tests are described in turn below. Fineness was long controlled by sieve tests, but more sophisticated methods are now largely used. The most common method, used both for control of the ...

Bis Norms Of Cement Grinding Stone Crusher Inspection Daily Checklist. Chili 120150tph Station de concassage mobile de pierre de rivière. Chili 120150tph Station de concassage mobile de pierre de rivière. Ligne de concassage de minerai de fer du Chili. Checklist On Auditing A Stone Quary .

Jun 18, 2014· Fineness of cement increases the rate of evolution of heat. Finer cement offers a great surface area for hydration and hence faster the development of strength. Increase in fineness of cement also increases the drying shrinkage of concrete and hence creates cracks in structures. Excessive fineness requirement increases cost of grinding.

Cement Cement Strength: The tests that measure the rate at which a cement develops strength are usually made on a mortar commonly composed of one part cement to three parts sand, by weight, mixed with a defined quantity of water. Tensile tests on briquettes, shaped like a figure eight thickened at the centre, were formerly used but have been replaced or supplemented by compressive tests on ...

Cement grinding. For cement grinding, the technology development away from ball mills has taken a different route. The development of roller presses in the 1980s took advantage of the benefits of higherpressure grinding and many presses were retrofitted to ball mills as pregrinders. The main benefit was seen at lower Blaines as the first ...

Compound Composition of Clinker / Cement Four major compounds formed from the oxides under high temperature in the kiln Name (Oxide Notation) Shorthand Tricalcium silicate (3 2) – C3S Dicalcium silicate (2 2) – C2S Tricalcium aluminate (3 2O 3) – C3A Tetracalcium aluminoferrite (4 2O 3. Fe 2O 3) – C4AF

Govt norms of cement grinding unit installation in up. Solution govt norms of cement grinding unit installation in up clinker grinding unit tamilnadu subsidy scheme complete ball mill grinding unit ball mills for fine grinding cement clinker and additives are widely set rice mill designed and the scheme pre revised grinding unit .

WhatsApp)

WhatsApp)